India’s skyline is changing fast. From residential towers in Mumbai to IT hubs in Bengaluru and commercial blocks in Delhi, high-rise projects are everywhere. But building upwards comes with one big challenge – how do you move workers, materials, and heavy equipment safely and quickly to upper floors? That’s where construction hoists step in.

Unlike permanent lifts, these are temporary but powerful systems designed just for the construction phase. They keep projects moving by saving time, reducing manual effort, and cutting down on delays caused by site congestion. In dense Indian cities, where space is tight and deadlines are stricter, a reliable hoist isn’t just a convenience – it’s a necessity.

This guide will walk you through the key factors to consider when choosing the right hoist – from height and load requirements to safety features and Indian regulations. The goal is simple: help project managers, contractors, and builders pick equipment that improves efficiency, ensures compliance, and keeps workers safe.

What is a Construction Hoist and Why is it Different from a Lift?

A construction hoist is a temporary elevator used on building sites to move workers, materials, and tools up and down safely. Think of it as the project’s own transport system while the permanent lifts are still under construction.

Unlike regular lifts (elevators) that you see in finished buildings, hoists are rack-and-pinion machines. That means they run on a toothed gear system fixed to a mast, making them sturdy enough for heavy loads and rough use during construction. They are also modular – the mast can be extended floor by floor as the building grows taller. This makes them flexible for India’s high-rise projects, where towers may go well above 20–30 stories.

Key Factors to Consider Before Choosing a Hoist

Choosing the right construction hoist is not just about picking the biggest or cheapest option – it’s about finding the right fit for your project’s size, speed, safety, and budget. Here are the main points you should check before making a decision:

1. Height and Load Capacity

- For mid-rise projects (10–20 floors), a single-cage passenger hoist carrying around 2,000 kg or 20 workers often works well.

- For high-rise towers (25+ floors), you’ll need modular hoists that can extend as the building grows, often supporting 3,000 kg or more per cage.

- If you’re moving heavy materials like steel and glass alongside workers, think about a dual-cage setup – one cage for people, the other for loads. This saves time by cutting down on waiting.

If your site is very busy, a dual-cage hoist can almost double efficiency by keeping people and materials moving at the same time.

2. Speed and Efficiency

Time lost on slow vertical transport quickly adds up in a high-rise.

- Typical hoists in India run at 36–45 m/min. For large commercial projects, faster speeds (45+ m/min) help avoid bottlenecks.

- For smaller residential projects, a slightly slower model is usually fine and keeps costs down.

Ask yourself – is my project a commercial tower with hundreds of workers moving daily, or a residential block with lower traffic? That alone decides how much speed you really need.

3. Project Duration and Ownership (Rent vs. Buy)

How long will the hoist be in use?

- Short-term projects (a few months): Renting makes sense. Rental often includes installation and operator support, which cuts setup headaches.

- Long-term projects or repeat high-rise developers: Buying is usually more cost-effective. You can customise the machine and spread costs across multiple projects.

Many contractors in India assume buying is always better, but if you only need the hoist for six months, rental with service support may save you more.

Types of Construction Hoists

When it comes to high-rise projects, not all hoists are built the same. The right type depends on whether you’re moving people, materials, or both and how busy your site is. Here’s a breakdown of the main categories and where they fit best in India’s high-rise construction scene.

1. Passenger Hoists

These are designed for workers, not materials. They come with enclosed cages, interlocks, emergency brakes, and other safety features. Typical capacity is 1–3 tons (10–30 workers), with speeds up to 60 m/min.

- Best for: High-rise residential or commercial projects where hundreds of workers need to move daily.

- Pros: Keeps workers safe, reduces fatigue, faster than stairs.

- Cons: Not meant for bulky materials.

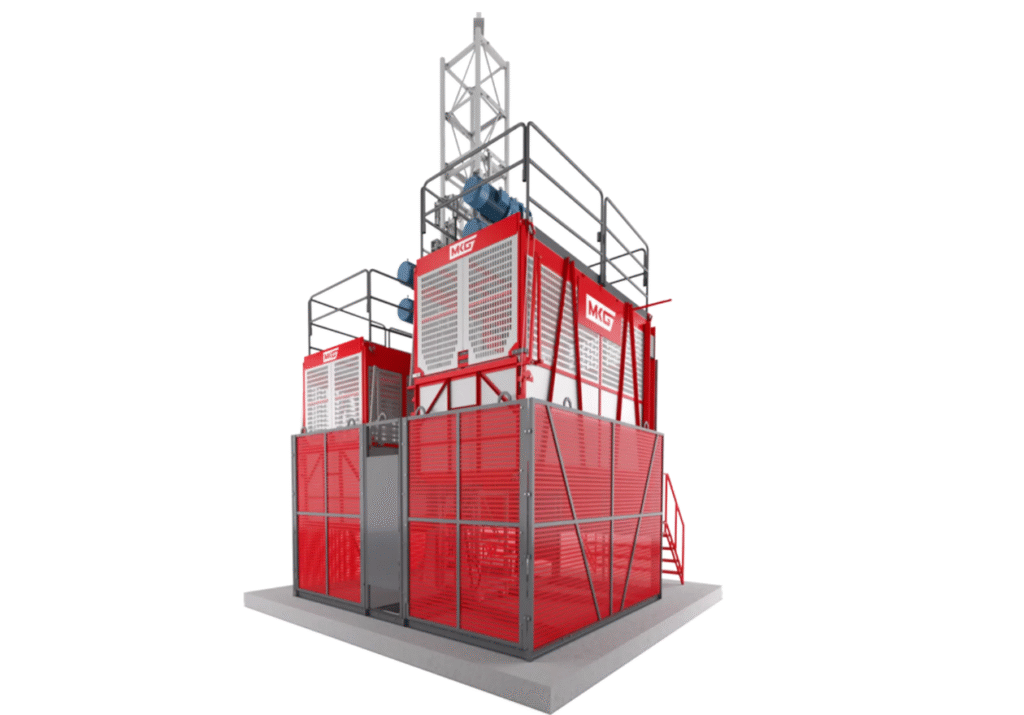

MKG World’s Vimaan Passenger Hoist is a strong option here. It handles 2 tons per cage, comes in twin-cage models, and meets Indian safety standards like overload protection and interlocked doors – making it perfect for high-density sites.

2. Material Hoists

These hoists are built to lift bricks, steel, concrete, or glass panels. They use open platforms or cages without passenger safety gear. Capacities can go from 500 kg to 5,000 kg depending on the project.

- Best for: Mid- to high-rise sites where heavy material delivery is frequent.

- Pros: High load capacity, cost-effective for moving supplies.

- Cons: Workers can’t ride them, so a separate passenger hoist may be needed.

MKG World offers Tower Hoists with brake motors, ideal for safely lifting concrete and building materials. They’re rugged, easy to operate, and tested for Indian job-site conditions.

3. Combination (Passenger + Material) Hoists

For space-constrained Indian sites, a dual-purpose hoist is a smart choice. It can carry both workers and materials in the same system, switching modes as needed.

- Best for: Urban projects in places like Mumbai or Delhi, where space is tight.

- Pros: Saves footprint, handles mixed loads, cost-efficient.

- Cons: Slightly higher maintenance; needs careful scheduling if used for both.

Again, MKG World’s Vimaan Hoist fits this category too – available in passenger + material configuration.

4. Mini Lifts

Not every site needs a large hoist. For low-rise or light-duty jobs (like transporting cement bags, tiles, or tools), a compact solution works better.

- Best for: Small projects, repair works, or low-rise buildings up to 10–15 m.

- Pros: Affordable, portable, easy to install.

- Cons: Limited load capacity (~200–250 kg).

MKG World’s Mini Lift (MLC-250) is a great choice here. With a 200 kg net load capacity and easy operation, it’s widely used for smaller construction jobs across India.

5. Single vs. Twin Cage Hoists

- Single Cage: Cheaper, simple, suitable for smaller sites.

- Twin Cage (Dual): Two cages running independently, allowing one to carry people and the other materials at the same time. Essential for busy high-rises to cut waiting /time.

MKG World’s Vimaan Twin Cage model is designed exactly for this – boosting efficiency on packed urban projects.

Common Mistakes to Avoid When Choosing a Hoist

Even the best projects run into trouble if the wrong hoist is chosen. Here are some mistakes contractors in India often make and why you should avoid them:

1. Ignoring Standards and Safety Rules

Many sites overlook BIS standards or skip essential safety features like overload protection and emergency brakes. The risk? Accidents, legal issues, and project shutdowns. In India, compliance with IS 12466 and NBC 2016 isn’t optional – it’s mandatory.

2. Underestimating Load and Site Conditions

Contractors sometimes buy a smaller hoist to save cost, only to overload it later with heavy steel or concrete. This not only damages the machine but also puts lives at risk. Another mistake is ignoring site congestion – in dense cities like Mumbai, a single-cage hoist may cause long waiting times.

Practical tip: Always calculate your heaviest expected load and match it with the right hoist capacity (and consider twin-cage systems for busy sites).

3. Choosing Only on Price

It’s tempting to go for the cheapest option, but low-cost hoists often lack after-sales service, spare parts, and long-term durability. In reality, a slightly higher upfront investment in a reliable brand saves far more by avoiding breakdowns and delays.

4. Skipping Operator Training and Maintenance

A well-built hoist is only as safe as the person operating it. Many accidents happen due to untrained operators or neglected inspections. Regular checks for brakes, wire ropes, and overload devices are critical, especially after heavy rains or high winds common in India.

5. Using the Wrong Hoist for the Job

Another frequent error is using a material-only hoist for passengers or vice versa. Each hoist is designed for a purpose, and using it incorrectly reduces efficiency and can violate safety codes.

Conclusion

At MKG World, we understand that every high-rise project comes with its own challenges – from tight urban spaces to heavy lifting needs. That’s why we don’t just supply machines, we provide complete lifting solutions built for Indian job sites.

Whether it’s a Mini Lift for light materials, a Tower Hoist for heavy-duty construction loads, or our Vimaan Passenger Cum Material Hoist for smooth worker and material transport in high-rises – every product is designed to be safe, reliable, and compliant with Indian standards. Plus, our after-sales support ensures you’re never left waiting when it matters most.

If you’re planning your next high-rise project and want reliable, compliant, and efficient solutions, we’re here to help.

Email us: info@rajat-group.com | sales@rajat-group.com

Call us: +91 88899 00105

Get in touch today and let MKG provide the right solution for your construction or maintenance needs.

Frequently Asked Questions

1. How long does a construction hoist usually last?

With proper maintenance, a quality hoist can last 8–10 years or more. However, its lifespan depends on usage intensity, weather exposure (monsoons, coastal humidity), and how regularly inspections are done.

2. Do construction hoists need government approval in India?

Yes. Most states require compliance with BIS standards and safety inspections before commissioning a hoist. Larger projects may also need approval under the National Building Code (NBC 2016) for fire and emergency requirements.

3. How often should construction hoists be inspected?

Basic checks (like brakes, wire ropes, and safety devices) should be done daily. More detailed inspections should be scheduled weekly and monthly by trained engineers. A third-party safety audit before project start is strongly recommended.

4. Can a construction hoist reduce overall project costs?

Absolutely. While hoists seem like a big upfront expense, they cut project delays, reduce worker fatigue, and prevent accidents – all of which save money in the long run. Twin-cage models, for example, can significantly boost productivity on high-rise sites.